Transmission distance is the NO.1 factor that designers would take into account when deploying network because the exact transmission distance that fiber optic can support is usually limited by many factors. How to avoid this situation? Is there a method that can help us to achieve long transmission distance? This article today will pay attention to the factors that limit optical transmission distance and provide some practical solutions accordingly.

Optical Cable Type

The maximum transmission distance of fiber optic cable (single-mode or multi-mode fiber) is typical limited by dispersion. Multi-mode transmission is affected by the modal dispersion, while single-mode fiber is limited by chromatic dispersion. The core of the single-mode fiber optic is much smaller than that of multi-mode fiber. That’s why single-mode can transmit over longer distance than multi-mode fiber. Most designers should attach importance to review the specifications and limitations of transceivers and have them work optimally in their devices. Then it is highly recommended that we use multi-mode fiber optic transceivers for shorter distances and single-mode fiber for long distance transceivers. Take QFX-QSFP-40G-SR4 as an example, it is the compatible Juniper 40GBASE-SR4 QSFP+ transceiver that operates over multi-mode fiber. Although our application may call for an long reach, we can only use multi-mode fiber on this module for a distance of 150m. If you use an single-mode fiber on this transceiver, it may cause an error.

The maximum transmission distance of fiber optic cable (single-mode or multi-mode fiber) is typical limited by dispersion. Multi-mode transmission is affected by the modal dispersion, while single-mode fiber is limited by chromatic dispersion. The core of the single-mode fiber optic is much smaller than that of multi-mode fiber. That’s why single-mode can transmit over longer distance than multi-mode fiber. Most designers should attach importance to review the specifications and limitations of transceivers and have them work optimally in their devices. Then it is highly recommended that we use multi-mode fiber optic transceivers for shorter distances and single-mode fiber for long distance transceivers. Take QFX-QSFP-40G-SR4 as an example, it is the compatible Juniper 40GBASE-SR4 QSFP+ transceiver that operates over multi-mode fiber. Although our application may call for an long reach, we can only use multi-mode fiber on this module for a distance of 150m. If you use an single-mode fiber on this transceiver, it may cause an error.

Light Source of Fiber Optic Transceiver

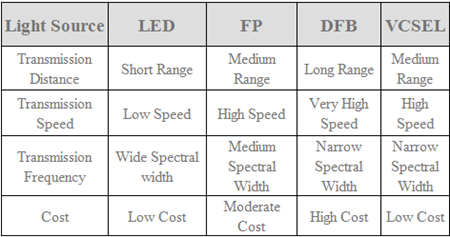

Optical signals must be converted into electronic signals over the optical transceiver because most of the devices are electric based. And the conversion between them is largely depend on a LED (light emitting diode) or a laser diode inside the optical transceiver. Fabry Perot (FP) laser, Distributed Feedback (DFB) laser and Vertical-Cavity Surface-Emitting (VCSEL) laser are the common type of light source inside the transceiver module that may have an impact on optical transmission distance. Table 1 present a comparison between these light sources, which would be a factor that designers should take into account when picking an optical transceiver to achieve long transceiver distance.

Optical signals must be converted into electronic signals over the optical transceiver because most of the devices are electric based. And the conversion between them is largely depend on a LED (light emitting diode) or a laser diode inside the optical transceiver. Fabry Perot (FP) laser, Distributed Feedback (DFB) laser and Vertical-Cavity Surface-Emitting (VCSEL) laser are the common type of light source inside the transceiver module that may have an impact on optical transmission distance. Table 1 present a comparison between these light sources, which would be a factor that designers should take into account when picking an optical transceiver to achieve long transceiver distance.

Splice and Optical Connectors

The signal loss can be caused when passing through fibers or connector, which will largely affect the transmission distance. Fusion splicing is the method of joining two optical fibers end-to-end using heat. Alternatives to fusion splicing include using optical fiber connectors or mechanical splices both of which have in general higher insertion losses, lower reliability and higher return losses than fusion splicing. Network designers nowadays choose to use fusion splicing because the goal of such a way that optical signal passing through the fibers is not attenuated or reflected back by the splice. In other word, fusion splicing will have less effect in the transmission distance that fiber optic cable can support. Here are some tips for fusion splicing that may help you.

The signal loss can be caused when passing through fibers or connector, which will largely affect the transmission distance. Fusion splicing is the method of joining two optical fibers end-to-end using heat. Alternatives to fusion splicing include using optical fiber connectors or mechanical splices both of which have in general higher insertion losses, lower reliability and higher return losses than fusion splicing. Network designers nowadays choose to use fusion splicing because the goal of such a way that optical signal passing through the fibers is not attenuated or reflected back by the splice. In other word, fusion splicing will have less effect in the transmission distance that fiber optic cable can support. Here are some tips for fusion splicing that may help you.

1. Clean the fiber

2. Stripping the coating off the two fibers that will be spliced together

3. Cleaning of the stripped fiber

4. Each fiber must be cleaved so that its end-face is perfectly flat and perpendicular to the axis of the fiber

5. Aligning of two end-faces of the fibers. This is normally done by the splicing machine by means of: fixed V-groove, optical core alignment, cladding alignment or local injection and detection of light (LID)

6. The two fibers are fused together

7. Check mechanical strength of the splice (normally done by the splicing machine)

8. The bare fiber area around the splice is protected with a splice protector and use the same batch of high quality bare fiber on a route

9. Choose installers who have adequate training and rich experience in fiber connection

2. Stripping the coating off the two fibers that will be spliced together

3. Cleaning of the stripped fiber

4. Each fiber must be cleaved so that its end-face is perfectly flat and perpendicular to the axis of the fiber

5. Aligning of two end-faces of the fibers. This is normally done by the splicing machine by means of: fixed V-groove, optical core alignment, cladding alignment or local injection and detection of light (LID)

6. The two fibers are fused together

7. Check mechanical strength of the splice (normally done by the splicing machine)

8. The bare fiber area around the splice is protected with a splice protector and use the same batch of high quality bare fiber on a route

9. Choose installers who have adequate training and rich experience in fiber connection

As noted above, the optical transmission distance is affected by a variety of factors, like fiber optic cable type, light source of transceiver, and splices and connectors. Frequency of transmission and bandwidth should also be considered to minimum the limitations on the transmission distance. I hope all the suggestions that I have provided above can help you to achieve long transmission distance. Fiberstore offers a variety of high-quality fiber optic cable and optical transceiver modules (like the popular 40G QSFP) that are fully tested. Meanwhile, components like repeater and optical amplifiers are also useful to support the long distance transmission. If you have any interest in our products, please contact us directly.

Thank you for sharing the information.

ReplyDeletePassive Networking

Structured Cabling

Thank you for the information structured cabling service

ReplyDelete