Optical technology nowadays has made huge progress to meet the growing requirement for high-density multifiber applications in telecommunication field. Fiber optic splitter, as an indispensable equipment for fiber optic network, enables signals on an optical fiber to be distributed among two or more fibers. Optical cable splitter typically can be divided into FBT (Fused Biconical Taper) splitter and PLC (Planar Lightwave Circuit) splitter. Each type has advantages and disadvantages when deploying them in a passive optical network. This article will guide you to form a basic knowledge about fiber optic splitter, especially FBT splitter and PLC splitter.

Fiber Optic Splitter

Optical splitter, also known as a beam splitter, is based on a quartz substrate of an integrated waveguide optical power distribution device, which is used to split the fiber optic light evenly into several parts at a certain ratio. Since splitters contain no electronics nor require power, they are an integral component and widely used in most fiber optic networks. The diagram below shows how light in a single input fiber can split between four individual fibers (1x4).

Optical splitters are manufactured commonly in two types according to its working principle—FBT (Fused Biconical Taper) splitter and PLC (Planar Lightwave Circuit) splitter. Splitters can be built using a variety of single mode fiber patch cables and multimode optical fibers and with most connector types for various applications.

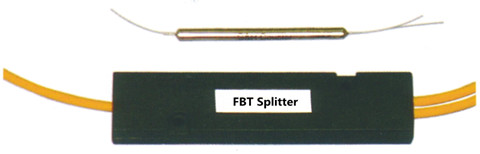

FBT Splitter—FBT is a traditional technology that two fibers are typically twisted and fused together while the assembly is being elongated and tapered. The fused fibers are protected by a glass substrate and then protected by a stainless steel tube, typically 3mm diameter by 54mm long. FBT splitters are widely accepted and used in passive optical networks, especially for instances where the split configuration is not more than 1×4. The slight drawback of this technology is when larger split configurations such as 1×16, 1×32 and 1×64 are needed. The following picture shows a FBT splitter with a split configuration of 1×2.

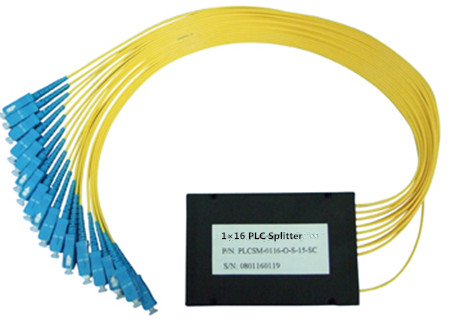

PLC splitter—A PLC splitter is a micro-optical component based on planar lightwave circuit technology and provides a low cost light distribution solution with small form factor and high reliability. It is manufactured using silica glass waveguide circuits that are aligned with a V-groove fiber array chip that uses ribbon fiber. Once everything is aligned and bonded, it is then packaged inside a miniature housing. PLC Splitter has high quality performance, such as low insertion loss, low PDL (Polarization Dependent Loss), high return loss and excellent uniformity over a wide wavelength range from 1260 nm to 1620 nm and have an operating temperature -40°C to +85°C. The following picture shows a PLC splitter connected with LC LC single mode patch cord.

Advantages and Disadvantages of FBT and PLC splitters

1. FBT—Fused Biconical Splitter

1. FBT—Fused Biconical Splitter

FBT splitter is one of the most common splitters, which is widely accepted and used in passive networks. FBT splitter is designed for power splitting and tapping in telecommunication equipment, CATV network, and test equipment.

Advantages

- The product is well-known and is easy to produce, thus reducing cost of production.

Splitter ratios can be customized. - Can work on three different operating bands (850nm, 131 Onm, and 1550nm).

Disadvantages

- Restricted to its operating wavelength.

- Because of errors in equality insertion loss, the maximum insertion loss will vary depending on the split and increase substantially for those splits over 1:8.

- Because an exact equal ratio cannot be ensured, transmission distance can be affected.

- High temperature dependent loss (TDL). The operating temperature range is 23 °F- 167 °F. Any changes in temperature can affect the insertion loss.

- The larger the split, the larger the encapsulation module.

- Susceptible to failure due to extreme temperatures or improper handling.

2. PLC—Planar Lightwave Circuit Splitter

PLC splitter is a hot research at home and abroad today, with a good prospect of application, which is used to distribute or combine optical signals. It is based on planar lightwave circuit technology and provides a low cost light distribution solution with small form factor and high reliability.

Advantages

- Suitable for multiple operating wavelengths (1260nm–1650nm); unstinted.

- Equal splitter ratios for all branches.

- Compact configuration; smaller size; small occupation space.

- Good stability across all ratios.

- High quality; low failure rate.

Disadvantages

- Complicated production process.

- Costlier than the FBT splitter in the smaller ratios.

Conclusion

Similar in size and outer appearance, PLC and FBT splitters provide data and video access for business and private customers, but internally the technologies behind these types vary, thus giving service providers a possibility to choose a more appropriate solution. FS.COM provides a full range of optical fiber splitters for you to choose from. If you are interested, you can have a look at it.

Thank you for the information Fiber optic network cabling

ReplyDeleteThank you for the information structured cabling service

ReplyDelete