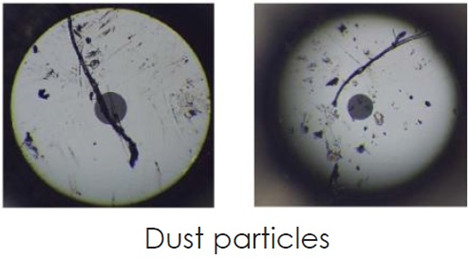

Fiber optic technicians are aware that dirty connections can cause attenuation, but they may not realize that it can also cause bit errors or slowdown of the network. Therefore, keeping the fiber optic connector endfaces clean is one of the most overlooked aspects of fiber optic maintenance and troubleshooting. Today’s article will describe the detailed information about how dirty fiber optic connector can cause slowdown of the network.

Brief Overview of Fiber Optic Connectors

A fiber optic connector is urgently needed to the industry owing to the lower loss, lower cost, easier to terminate or solved some other perceived problem. As a result, about 100 fiber optic connectors have been introduced to the marketplace, but only a few represent the majority of the market. Commonly used fiber optic connector types like the SC, FC, LC, ST, MU, E2000, MTRJ, SMA , DIN as well as MTP & MPO etc, which are widely used in the termination of fiber optic cables, such as fiber optic pigtail, fiber optic patch cables and so on.

How Does the Dirty Fiber Optic Connector Cause Bit Errors?

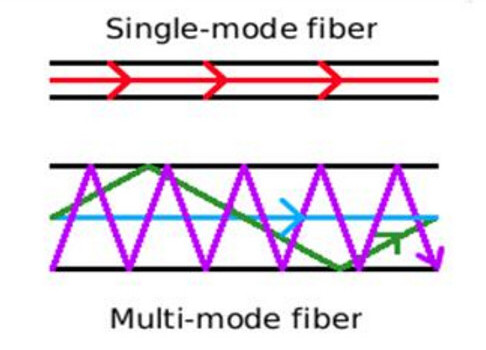

Of course, the dirty fiber connection will cause bit errors as the contamination degrades the signal quality. In fact, the signal comes in a beam of light traveling through the fiber’s core. When the light travels through the fiber core, it has a refractive index value. But when the light beam comes into contact with end face contamination, it will enter a second medium which has different refractive index value. That’s the reason why it causes the bit error rates.

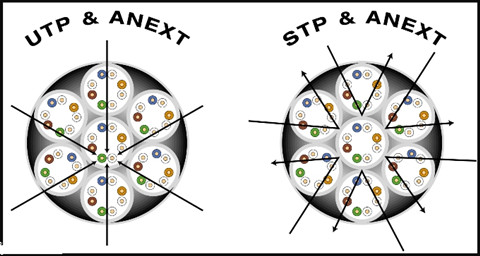

Figure 1: dust particles under the microscope

Sometimes, in fiber optic network, we need to mate two fiber optic connectors together. Will the mating prevent fiber optic connector from contamination? The answer is yes. There is no need to worry about dust with physical contact connectors as long as they were cleaned before the mating process. When the two ferrules are physically mated, the mating force for most single fiber industry standard connectors is around 1kg or about 2.2lbs. If you calculate the force of what 2.2lbs in a 200μm, that comes to 45,000psi which is why contaminate migration is not a problem even in a dusty environment. The following part will provide some answers to some common questions of end users.

Will the Dust Cap Make Fiber Endface Clean?

No, customers should never assume that a capped cable assemblies is clean when taking out of the bag. Dust and mold release agents are the two common contaminates but nearly invisible for the human eyes. The primary purpose of the end cap is to protect the ferrule end face from scratch and pitting defects. It does not protect the ferrule end face from contamination.

If a customer buys a new fiber jumper from the manufacturer and inspects it after taking the end caps off, it would not be uncommon to see some small amount of on contamination on the endface. This does not mean that the jumper manufacturer’s quality process are lacking. All manufacturers experience this. The customer just needs to work smartly and realize that the end cap is just for protecting against scratches. The best practice is to inspect the ferrule, clean if necessary and re-inspect before mating. If the customer does not have a ferrule scope available, then cleaning both connectors end faces before mating will significantly reduce the likelihood of damage and cross contamination.

How to Keep the Fiber Optic Connectors Clean?

Keeping fiber connections clean is different from any other type of cleaning due to the relative sizes of the connectors compared to the particles and contaminants that typically reside on them. Also we need to be diligent in their maintenance by cleaning the connectors every time before they are mated and after each un-mating. Static charges attract dust to the fiber connectors and prevent them from falling off even when blown with a can of compressed air. As we have discussed in the above article, dust caps are primarily used to protect the ferrule and can actually make a clean connector dirty due to their tendency to keep a static charge.

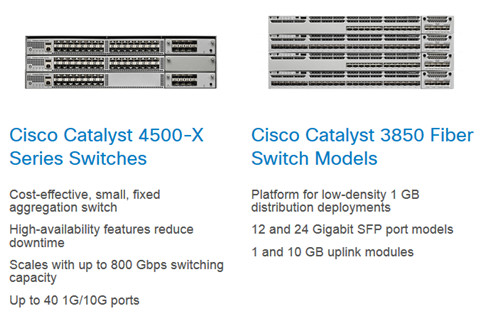

Figure 2: use one-click cleaner to clean the MPO cable

The mechanical cleaning tools like the One-Click cleaners are widely used in the optical fields. . One-click cleaner is designed to clean male connectors, female bulkhead adapters, fiber patch cables and test equipment. It cleans the ferrule endface removing from dust, oil and other contamination without scratching the endface. Although it is the most cost-effective and time-saving solution for cleaning fiber optic connectors, it has a limited contact region and will never be able to clean the connector’s end face. Therefore, another fiber optic cleaner has given to birth—Fiber Optic Cassette Cleaner. The cassette cleaner can wipe away contamination from optical connector endface with ease. I’s very easy to use and suitable for LC/MU/SC/FC/ST/MPO/MTRJ connectors. Usually, the body of this cleaner is made from antistatic materials which will not produce dust.

Is Dry Cleaning a Better Solution?

Besides the mechanical cleaning tools, there are two basic methods :dry cleaning and wet cleaning. There are two distinct advantages a wet cleaning process has over the dry process. The first process is static dissipation and the second is the cleaning solvent’s ability to loosen up harden contaminates from the ferrule end face without causing permanent defects to the end face.

On the other hand, the dry wiping process that an operator would do using a Fiber Optic Cassette Cleaner or One-Click cleaner relies on contact friction to remove contamination. When two materials are rubbed together, there is a transfer of electrons between the two surfaces and the imbalance on the surface creates a charged electric force we call static electricity. The two surfaces, one charged positive and the other negative, will try to pull in surrounding particles to being the charge back into a neutral balance. This attraction pulls in the dust particulates in the air and the wear debris on the connector body and adapter. The introduction of a cleaning solvent during a wet-dry cleaning process introduces static dissipative medium for the charge so that it does not stay on the ferrule surface.

Conclusion

End users should be wise to think of the environment his connectors are being exposed before learn to keep fiber optic connector clean. Because a large enough piece of dust particulate residing somewhere on either ends will create problems. The best practice to avoid long-term problems and extend the life of your optical assemblies is to always inspect and remove any contamination regardless of the connector type. FS.COM offers a full range of fiber optics that can cater to your specific requirement. Bulk Ethernet cable, fiber jumpers, transceivers and DAC/AOC cables are in great selection. Please feel free to contact us.