Although the 40G/100G optical modules are on the very top trend for enterprise and data center for the interconnection, 10G transceiver modules are still in great demand. There are several types of 10G optical transceiver modules available for sale including the XENPAK, X2, XFP, small form-factor pluggable plus (SFP+) transceiver, of which 10g SFP transceiver (due to its small size and low power) is the most popular type for 10G network. According to the 10 Gigabit Ethernet standard, SFP+ transceiver can be classified into many categories: 10GBASE-SR SFP+, 10GBASE-LR SFP+, 10GBASE-ER SFP+, and 10GBASE-LRM SFP+. This article will focus on the introduction of the 10GBASE-LR SFP+ and 10GBASE-LRM SFP+ transceivers.

10GBASE-LR SFP+

10GBase-LR can support up to 10km over single-mode fiber and uses 1310nm lasers. There is no minimum distance for LR, either, therefore it is suitable for short connections over single mode fiber too. The Cisco 10GBASE-LR module supports a link length of 10 kilometers on standard single-mode fiber (SMF, G.652). FS.COM compatible 10GBASE-LR SFP+ transceiver possesses the same function as the original one with a much lower price than Amazon and ebay. The following image shows a Cisco Compatible SFP-10G-LR SFP+.

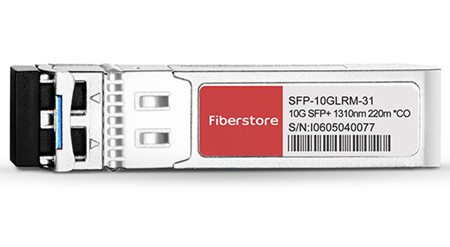

10GBASE-LRM SFP+

10GBASE-LRM still uses the 1310nm lasers, but it can only reach up to 220m over standard multimode fibers. The 10GBASE-LRM can be packaged in XFP and SFP+ form factors. FS.COM Cisco SFP-10G-LRM Compatible 10GBASE-LRM SFP+ supports link lengths of 220m on standard Fiber Distributed Data Interface (FDDI) grade multimode fiber (OM3/OM4). Every transceiver is individually tested on a full range of Cisco equipment and passed FS.COM’s testing with 100% compatibility. The following image shows a Cisco Compatible SFP-10G-LRM SFP+.

Besides the Cisco SFP-10G-LRM, there are a new type of the 10G SFP+ module for multimode fibers—SFP-10G-LRM2. It is a type of SFP+ transceivers compatible with the 10GBASE-LRM standard. SFP-10G-LRM2 can reach up to 2km over standard multimode fiber.

Contrast Between 10GBASE-LR and 10GBASE-LRM SFP+

At the first glimpse of the two terms—10GBase-LR and 10GBase-LRM, people usually have the misconception that they are similar with each other. In fact, 10GBase-LR and 10GBase-LRM meets different demands just as described in the above article. SFP-10G-LR optics (compatible with 10GBase-LR) supports a link length of 10km on standard single-mode fiber (SMF). SFP-10G-LRM (compatible with 10GBase-LRM) optics supports link lengths of 220m on standard Fiber Distributed Data Interface (FDDI) grade multimode fiber (MMF). When you use the OM1 or OM2 fibers connected with the 10GBase-LRM module, to make sure that specifications are met over FDDI-grade, the transmitter should be coupled through a mode conditioning patch cord. But it is fine when you use over the OM3 and OM4 fibers.

Conclusion

10G SFP+ transceiver is widely used to support communication standards including synchronous optical networking (SONET)/synchronous digital hierarchy (SDH), 10 Gigabit Ethernet and fibre channel. Both 10GBASE-LR and 10GBASE-LRM SFP+ wins its own place on the market. They cannot substitute for each other! FS.COM offers various compatible SFP+ transceivers for data centers, enterprise wiring closets, and service provider transport applications. 10G-SFP-SR, 10G-SFP-LR, 10G-SFP-LRM, 10G-SFP-LRM2, 10G-SFP-ER, 10G-SFP-ZR are all available in FS.COM. All of our SFP+ transceivers are tested and fully compatible with major brands like Cisco, HP, Juniper, Brocade and Finisar. For more information about 10G SFP+ modules, please visit fs.com.